Butter and ghee

Practical Action

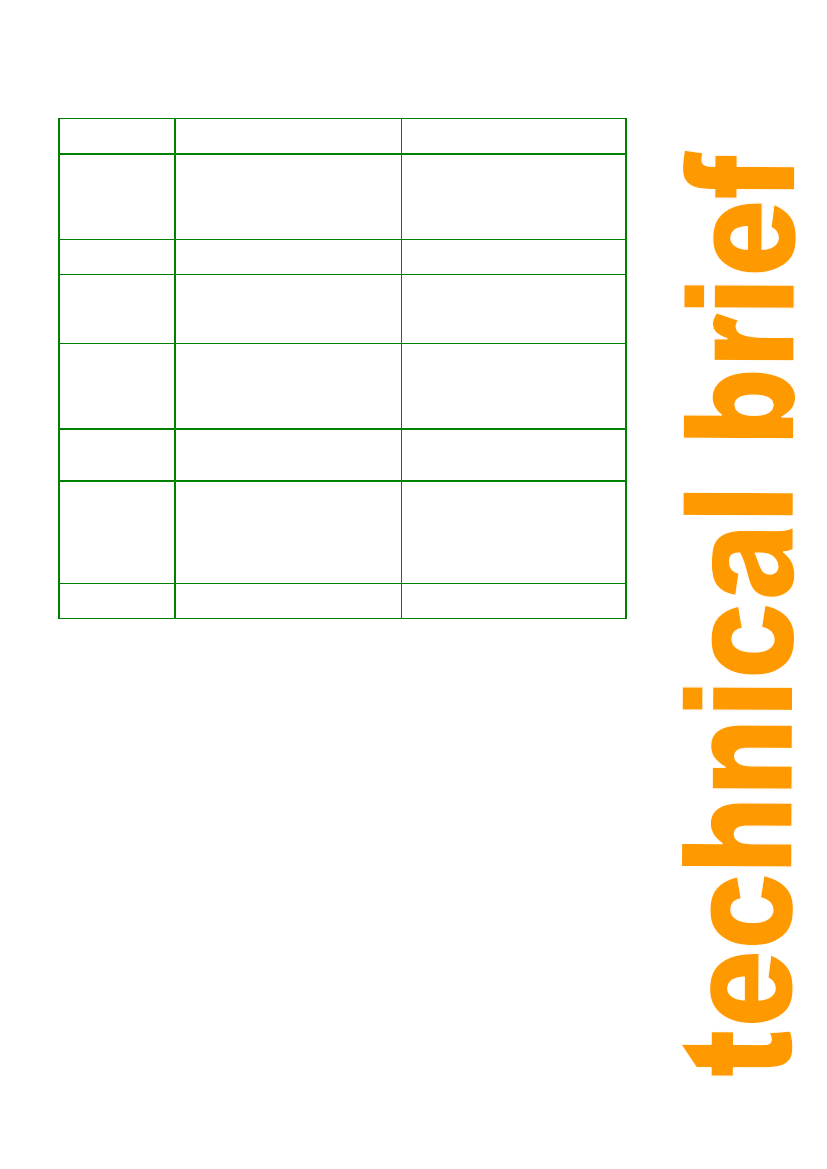

Pasteurise

Heat cream to destroy micro-

Check the temperature and time

cream

organisms and enzymes.

(e.g. 75oC +/- 2oC for 1 minute)

Chill

To age the cream

Temperature control at 6oC +/-

2oC. If the milk is too hot the milk

fat will be difficult to separate

and the yield of butter will be

reduced.

Churn

To produce butter

Check speed of churn, time of

churning (see text for details)

Wash

To remove buttermilk

Number of washings, check the

temperature of water and ensure it

is drinking quality (have it tested

at a laboratory)

Salting, working Adding salt for salted butter and Check the amount of salt added.

working the butter

Check the time of working to

ensure that salt is evenly

distributed through the butter and

it has uniform consistency

Pack

In greaseproof paper, foil or

Check the weight (e.g. 200g +/- 2

plastic wrapper, plastic pots with g net weight)

clip-on or foil lids.

Label

Attach label or print on the

Check that correct labels are

wrapper

used, that they are correctly

positioned, and show the correct

‘best before’ date (e.g. 9 months

from date of production) and

production batch number.

Store

Hold at 4-8oC in a refrigerator

Check refrigerator temperature is

6oC +/- 2oC

Table 3: Process control points in fresh butter production.

Product control

The main quality factors for butters are colour, texture, flavour and odour. For ghee they are

colour, clarity, flavour and odour. In butters, correct colour is due to control over heating, texture

is controlled by the extent to which cream is cooled, by the temperature when working the butter,

and temperature of storage. At higher temperatures the fat softens and results in a soft, greasy

butter, whereas butter from cooled milk fat is hard and stiff. The flavour/odour are controlled by

preventing rancidity. In ghee, the clarity is mainly due to proper filtering. The taste, colour and

odour of ghee depend on both the time of heating and preventing rancidity. Overheating

produces a burnt taste and odour and a darker colour. Incorrect packaging and storage

conditions accelerate the development of rancidity

Packaging and storage control

Rancidity during storage is reduced by using clean, dry containers and by keeping the stored

product away from light and heat. Iron and copper should not be used in any vessels, utensils or

packaging as these metals promote rancidity in the product.

Summary

Butter and ghee are low-risk dairy products that can have a high demand. They can be made

relatively easily at a small scale.

Equipment required

For fresh butter:

Butter churn.

6